Handpicked Wines owns six vineyards located in Mornington Peninsula, Yarra Valley, Tasmania and Barossa Valley, all of which are certified members of Sustainable Winegrowing Australia.

The Capella vineyard, on the Mornington Peninsula, was the first vineyard purchased by Handpicked Wines in 2013 and remains the company’s ‘spiritual home’. The Capella Vineyard is also organically certified, making it the first and only vineyard in Victoria to achieve both sustainability and organic certifications. This case study explores work conducted at this vineyard to understand the impacts of pest and disease and water management practices on greenhouse gas emissions.

The challenge – reducing greenhouse gas emissions while managing both organically and sustainably

Managing pests and diseases under Sustainable Winegrowing Australia certification requires demonstration that all methods of pest and disease control are considered (i.e. biological, cultural, mechanical, technological and chemical) and, if agrochemicals are selected, those with the lowest negative impact (on beneficial organisms and the overall environment) are chosen. Organic certification requires a further step, managing pests and diseases without the use of synthetic chemicals. Operating in this way requires close monitoring, careful selection of products and sometimes a higher frequency of spraying, which can result in higher greenhouse gas emissions.

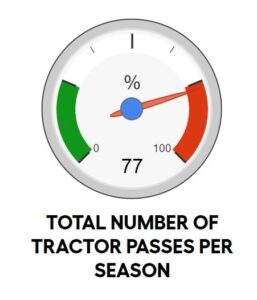

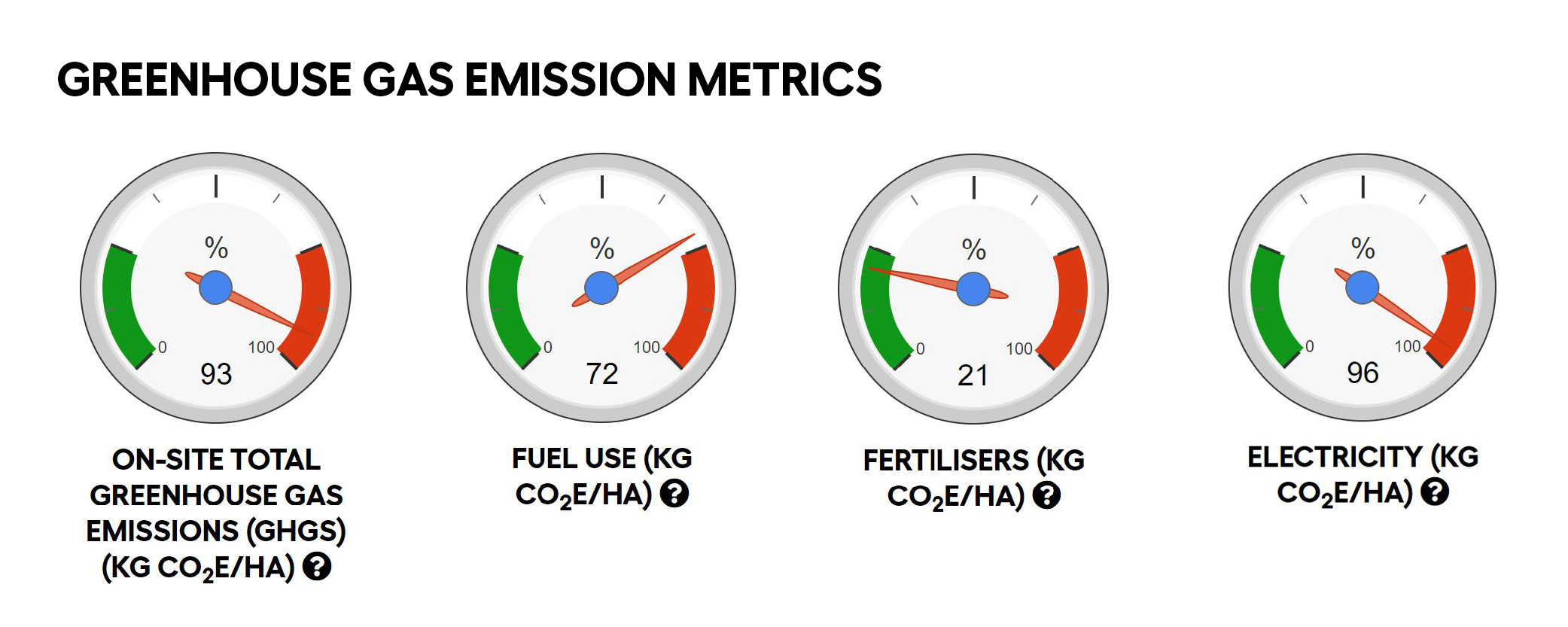

Once cultural controls such as canopy management have been implemented, controlling diseases in organic systems relies on the use of products such as sulfur, copper or fungi-derived sprays. These products are mostly preventative and rely on good coverage because they are not systemic within the vines. During high vine growth periods and when weather conditions are conducive to disease, it is necessary to apply the products more frequently to ensure adequate coverage to prevent disease establishment. A higher number of spray applications means more tractor passes through the vineyard per season (Figure 1) and higher greenhouse gas emissions, as those noted at Capella (Figure 2).

In the case of weed control, when herbicides are swapped for mechanical controls such as cultivation, the tractor pass is slower and requires more energy which also results in higher greenhouse gas emissions.

The other major contributor to greenhouse gas emissions at Capella Vineyard is onsite electricity use (Figure 2) that is mainly attributed to an electric pump which pressurises the irrigation system.

Figure 2. In 2021/22 the on-site greenhouse gas emissions per hectare for the Capella vineyard were in the highest 7% of members in the Port Philip Zone (left). Emissions from fuel and electricity were major contributors to the total emissions profile (right).

Implementing both organic and sustainable systems has brought more focus to monitoring the vineyard and considering alternative options for disease and weed control.

Solutions

Integrated solutions to reduce fuel use

A critical element of the pest and disease management program at the Capella vineyard is an integrated approach. Regular monitoring is conducted, including pheromone traps for monitoring light brown apple moth (LBAM) flights, checking for beneficial insects and weather tracking. This ensures that the timing of preventative sprays is maximised and, when they are required, the timing of application of surface sterilants is optimised. Midrow cover crops and five insectariums of Christmas bush and tea tree are used to host beneficial insect populations, with the goal that they will predate LBAM and other pests and reduce berry damage and potential entry points for Botrytis infection.

Midrow covercrops are alternated each row between a blend of Persian and crimson clovers, which supply nitrogen to the vines, and a mix of fifteen winter growing species. The clovers have the added benefit that they are low growing which enables the vine prunings to be effectively mulched. The cover crops also provide additional benefits to vineyard trafficability, enhanced soil organic matter, competition with weed species and a cover of mulch across the vineyard floor.

Herbicides are no longer used in the vineyard. These have been replaced with competitive cover crop species, weed control by hand and using a variety of mechanical implements. A 120 hp Fendt tractor is used for undervine weeding, with this model chosen for its small size, energy efficiency and the ability to operate multiple pieces of equipment at the same time.

There is a focus on ensuring that multiple operations occur with each tractor pass. Examples of this include:

- Clemens weeder on the front and slasher on the back

- Vine trimmer on the front and slasher on the back

- Weeders on the front and the back

The vineyard team are continuing to experiment with non-chemical undervine weed control methods using various tools and implements at different times of the year.

Improved irrigation efficiency to reduce electricity use

In the past, the vineyard irrigation system was operated manually, which meant that irrigation was only applied during the day. This resulted in high evaporative losses from the soil surface, and required more total irrigation and higher power demand. To overcome this, an automated irrigation system was installed three years ago, which enables irrigation at night and reduced water losses. The system is powered by four solar power systems and is connected wirelessly to the vineyard office and phones. The automated system also enables monitoring of pressure throughout the irrigation system and automated shut-off when faults occur, which prevents blow outs and lost time.

In addition to the irrigation system, there has been a focus on soil improvements. A program of compost and mulch application to the undervine areas has been implemented with the goal of further minimising moisture loss from the soil surface and increasing soil carbon accumulation and water-holding capacity of the soil.

Water use has decreased in the vineyard over the past three years; however, it is recognised that the seasons have received more rainfall during the growing season and less irrigation has been required. It is hoped that in seasons with low rainfall and high temperatures, the improvements made will make the vineyard more resilient to moisture stress.

The benefits

Implementing both organic and sustainable systems has brought more focus to monitoring the vineyard and considering alternative options for disease and weed control. The combined impact of the automated irrigation system and improved soil moisture monitoring and soil condition has reduced the volume of irrigation applied and improved water use efficiency. This has in turn reduced electricity use and greenhouse gas emissions, and the vineyard is achieving the same yields using less water, while fruit quality is improving over time.

Improved soil moisture monitoring and soil condition has reduced the volume of irrigation applied and improved water use efficiency. This has in turn reduced electricity use and greenhouse gas emissions.

ACKNOWLEDGEMENT

This case study was developed by the Australian Wine Research Institute with support from Handpicked Wines and funding from Wine Victoria and the Victorian State Government through the Growing Victorian Wine into the Future Program.